Phenolic Insulation: A Modern Solution for High-Performance HVAC Systems

As contractors constantly look to improve the products they offer customers, Phenolic insulation has emerged as a leading choice in HVAC systems, delivering superior thermal performance, air quality benefits, and glueless installation efficiency. With a rigid, closed-cell design, phenolic insulation offers a range of advantages over traditional materials, making it a compelling option for a variety of commercial applications.

Compared to other duct insulations, such as fiberglass or elastomeric, our phenolic insulation methods do not require any glue or pins for installation and instead utilize a liner retention clip that ensures you will have a rigid duct insulation that meets fire code requirements that glues can cause issues with.

Core Benefits for Lining Ducts with Phenolic Insulation

Unmatched Thermal Efficiency - High Insulated Values

Phenolic insulation panels are manufactured with a high closed-cell structure that reduces thermal conductivity for increased efficiency. This allows for high R-values with minimal thickness when compared to fibrous duct insulations. Such efficiency translates to reduced heating and cooling loads through less thermal transfer, cutting energy consumption and saving on long term costs.

Improved Indoor Air Quality - Fiberglass Free and Mold Resistant

Unlike fibrous materials often used as duct liners, phenolic insulation features a rigid, fiber-free core. Its smooth interior surface, typically faced with aluminum, minimizes the risk of particle shedding into the airstream. This design enhances air quality, a critical consideration in environments such as schools, hospitals, clean rooms, and food processing facilities.

Fire Safety and Code Compliance - Glueless Application for True NFPA 90A Compliance

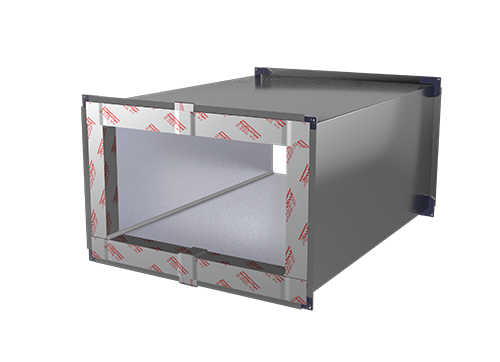

Phenolic insulation meets rigorous fire safety standards, including NFPA 90A, and achieves a 25/50 flame and smoke spread rating under ASTM E84. The thermoset properties of the phenolic core ensure it does not melt or produce flaming droplets in a fire, making it a safer choice for building occupants. Our patented method utilizes clips and modified Airtruss Ribs to ensure a firm hold of the phenolic insulation materials.

Streamlined installation for improved safety on the jobsite

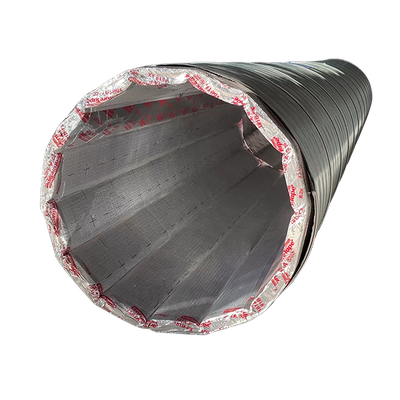

Step 1 - Cut Insulation

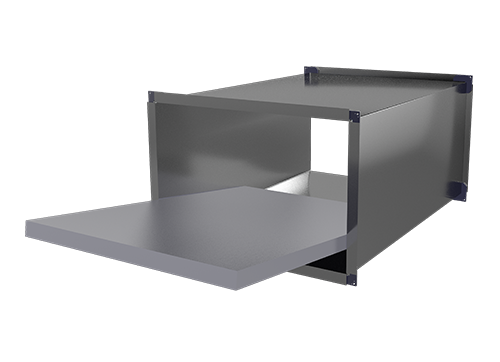

Step 2 - Apply Duct Liner

Step 3 - Retain Insulation

With our patented installation process, any shop can instantly get into the phenolic insulation business! Simply use a table saw to cut our phenolic insulation to size and easily apply it to your duct sections with our Liner Retention Clips that require no glue or pins to install. For fittings insulation, templates or additional fabrication machinery can extend this process to more complex offsets and elbows.

In addition to easy application your team will find that phenolic insulation is up to 75% lighter than traditional insulated sheet metal ductwork, simplifying handling and installation. The pre-insulated panels eliminate the need for additional insulation wrapping, reducing labor time and costs. Additionally, the rigid panels allow for precise cutting and a tight seal, minimizing air leakage and improving system efficiency.

Insulation Solutions for Engineers and Facility Owners

Phenolic insulation offers a forward-thinking solution for modern HVAC systems, addressing critical concerns like thermal performance, air quality, and moisture resistance. Its lightweight nature and ease of installation make it an efficient choice for installers, while its durability and safety features benefit building owners and occupants. By choosing phenolic insulation, projects can achieve superior HVAC performance and long-term energy efficiency, just like our other Thermaduct products. For more information on how you can start using phenolic insulation in your shops, contact Thermaduct today!

Related Articles

As energy codes push the required insulation values higher and higher, the need for better outdoor duct solutions is growing. Thermaduct products are designed to meet the needs of outdoor applications with a high level of energy and installation efficiency.

Low air leakage, IAQ duct solutions increase the energy efficiency and health of your building. Thermaduct is here to help. Our indoor products are lightweight solutions that reduce installation weight by over 70%.